Blue chromate conversion coating

€32.90

Available, delivery time: 1-3 Days

Product information "Blue chromate conversion coating"

Tifoo Blue chromate conversion coating – the product features at a glance:

- Ideal finish for zinc-plated layers

- Permanent protection for the zinc layers

- Ideally to be used with the Tifoo Zinc electrolyte

- 1000 ml content

- Excellent for beginners in the hobby electroplating

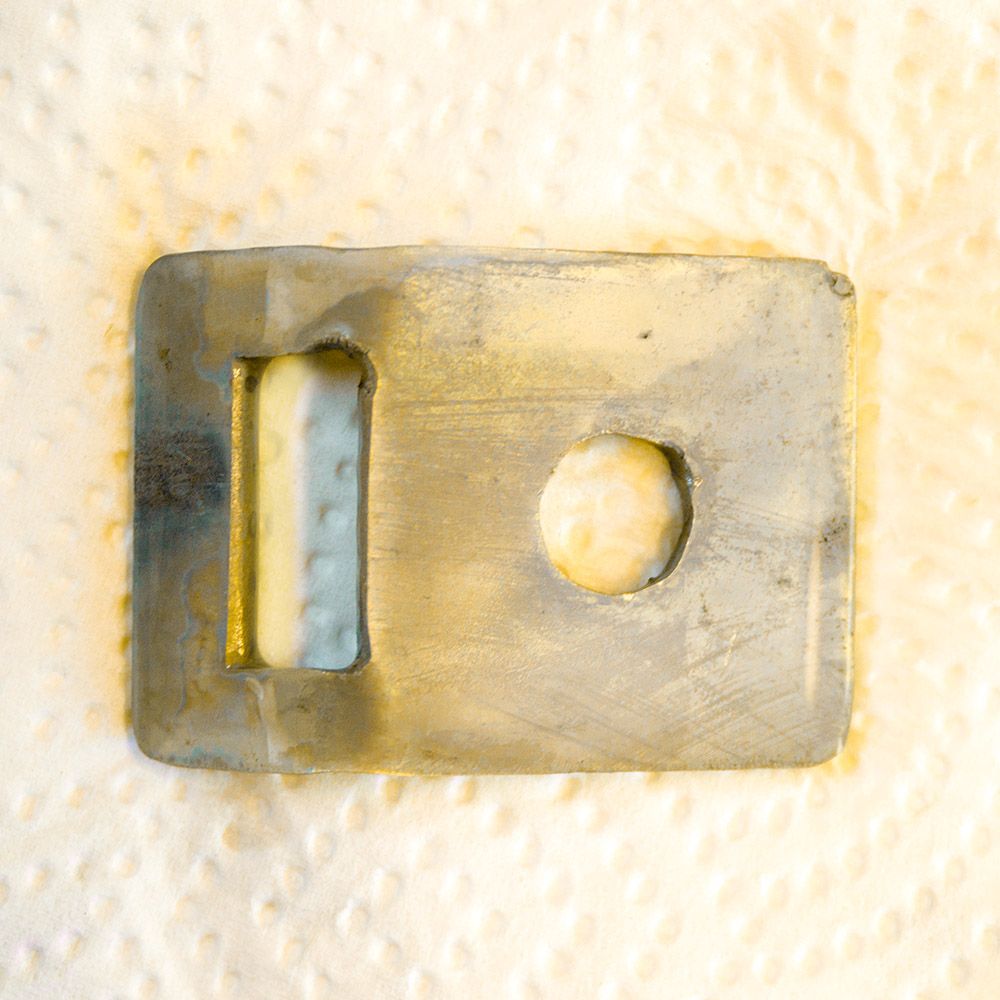

The chromate conversion coating is a quick corrosion protection for zinc and aluminium surfaces. Apply the protection layers (chromate layers) with the Tifoo Blue Chromate Conversion Coating (also called thick film passivation) and give zinc a noble finish. The term chromate conversion coating / thick film passivation of zinc describes the blue undertone that the tin surface will have after the treatment.

The chromate conversion coating is realized by dipping the object in a bath of Tifoo Blue Chromate Conversion Bluing. Without the need of any voltage or of working with other tools, you will obtain a thin layer of chemical conversion. The zinc surface is lightly removed with the thick film passivation. The zinc layer should consequently not be too thin, for that can cause erosion of the zinc. Please keep in mind that this is a Cr (III) based variation of blue chromate conversion coating (thick film passivation).

The current version based on Cr (VI) isnt allowed anymore in Germany for chromate conversion coating by the directive of the RoHS because of the toxicity of Cr (VI). Tifoo Blue Chromate Conversion Coating – the perfect corrosion protection for zinc surfaces. Easy self-made chromate conversion coating!

Application information:

Information on product safety:

The information on the product label must always be followed.

Manufacturer / Responsible person for the EU:

MARAWE GmbH & Co. KGAn d. Irler Höhe 3B

93055 Regensburg, Deutschland

+49 941 29020439

info@marawe.de

Login

Reviews are not verified as to the authenticity of purchases. Reviews may be from consumers who have not purchased or used the products.