You want to protect your vehicle from corrosion? Here you will find effective solutions!

We have developed various products to help you protect or repair your car, bicycle or other vehicles from wind and weather. The zinc complete set together with our yellow passivation and the Piranha rust converter offer the all-round protection you need for heavily stressed surfaces. For example, with the help of zinc electrolyte and pen electroplating (Brush), dents or paint damage to car bodies can be repaired and protected against corrosion - afterwards, affected areas are simply painted over or further treated. Exposed or moving zinc parts can be treated with our chromate coatings to create corrosion inhibition and a blue-matte or golden-yellow shine. Our rust converter "Rust Piranha" is the quick and easy solution for rusty iron surfaces.

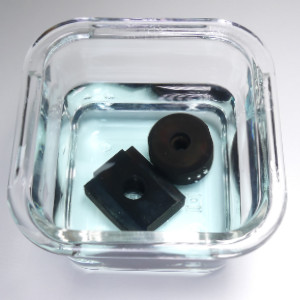

Yellow and blue chromating - attractive finishing with simultaneous corrosion protection

The Rust Piranha simply eats up rust spots - rust converter and primer in one!

Luxurious refinement of vehicle parts - many paths lead to the goal!

Frequently asked questions

Yes, this is possible with the help of our conductive copper varnish. The object is sprayed or brushed with copper conductive paint or copper conductive lacquer spray, which first creates a metallic layer. The object is then given its final conductivity in a galvanic bath with acidic bright copper electrolyte. This creates a continuous, conductive copper layer that can then be further treated like any other copper layer, e.g. by silver plating.

Rust Piranha can normally be painted over or treated further. However, please check on an inconspicuous spot whether the rust converter is compatible with your paint colour.

Our products for electroless silver plating only deposit on copper and brass as a base, as the products can only deposit silver with these materials. Accordingly, the products for electroless silver plating can NOT be deposited on silver. If copper or brass are coated, a thin silver layer of 200 - 300 nm is produced, which is intended for decorative purposes only. If you want a thicker silver layer on your object, the only process left is electroplating!

No, unfortunately that is not possible with these products.

In principle, it is possible to gold-plate some aluminium alloys with the Gold Star, but so far this only works with a few compositions. The success of the application can therefore not be guaranteed for all aluminium alloys.

The zinc object must be clean and free of residues such as dirt, oil or particles. The object is then degreased, e.g. with the TIFOO Galvano Degreaser. Depending on the size, the object is immersed in the yellow chromate for a few minutes. 3 minutes is a good guideline.

.jpg)